Despite the current restrictions for the COVID-19 virus some work is still carried out in our workshops – we follow the current recommendations from the authorities (keeping distance, frequent hand washing etc.).

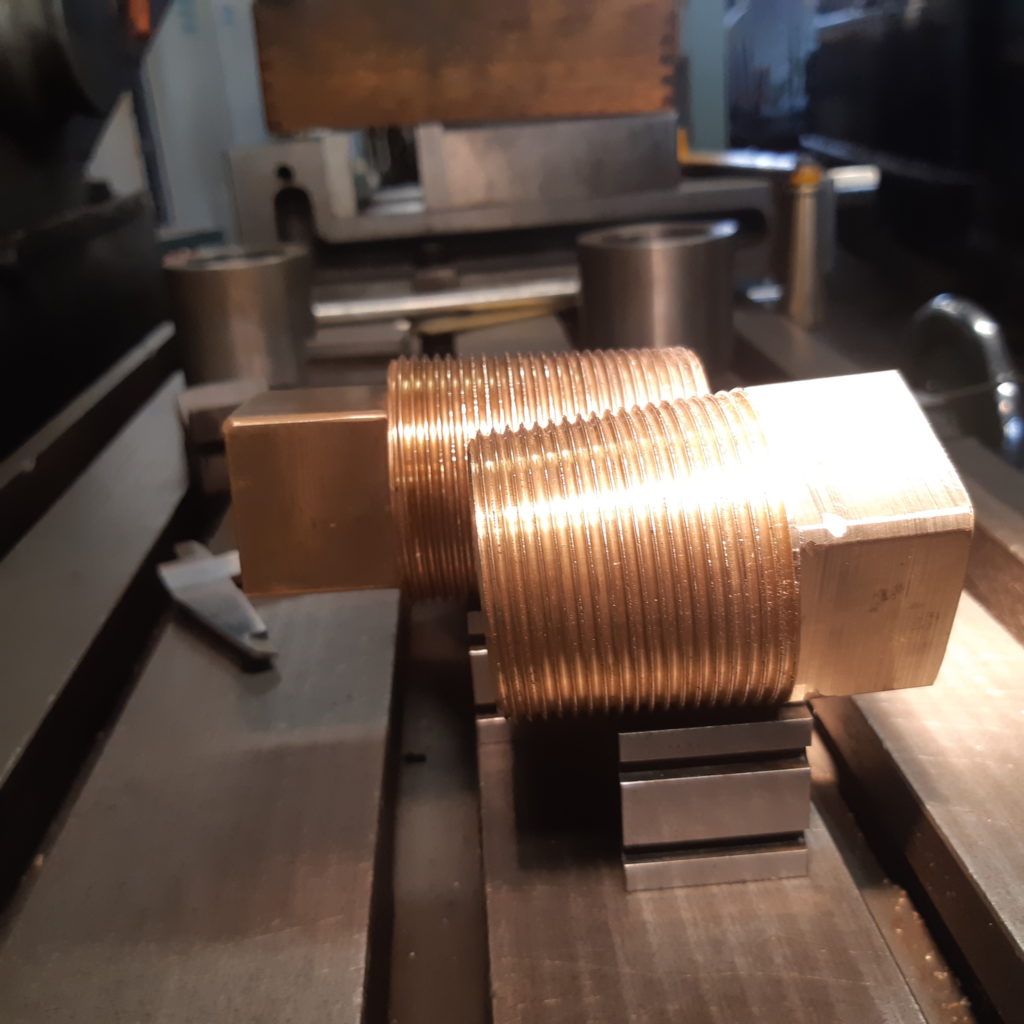

For JGJ 9 new wash-out plugs are being made for most of the positions on the boiler – a lot of work has gone into measuring the bushings to come to the correct diameter and conicity of the plugs.

In the center water tank, the area around a weld that we suspect has been made in the final years of service at Aspa bruk has been cleaned and a thin polyurethane based crack sealer has been applied – we have seen the leak on the outside of the tank in this area. After sealing the area has been painted with rust inhibitor and a final coating of black paint.

The cover plate around the steam pipes between the smoke box and the cylinders have some serious corrosion and the corroded sections will be cut away and new sheet metal welded in its place – then they will be riveted together again.

The left hand water tank has also been striped and now the major paint work on the loco is finished. The new mirror with the original frame in the cab has also been reinstalled – it is for the driver to be able to see the manometers without turning around when driving with the loco reversed.

Sometimes you feel the need to go a bit over the top when you want something to be just right – when the owner/number plates were removed from the cab not all of the screws could be saved for later use (they broke off) and their heads were non-standard, thus we made new ones from a standard hex brass screw